Lighter Commercial Vehicles.

Lower Costs.

Higher Payload.

Composite panels engineered for trailers, vans, and specialist commercial vehicles.

Why it matters

-

By reducing trailer weight by up to 2 tonnes (13.6m trailer), fleets see 7–9% proven fuel savings. That’s not just cost efficiency — it’s a direct carbon reduction at a time when every litre counts. Over a year, even modest fleets can save tens of thousands of pounds on diesel.

-

Our lightweight panels free up room for 3–6 additional roll cages per load (trailers) or 1–2 pallets in vans/rigids. That translates to fewer trips, more revenue per mile, and less wasted capacity — a win for efficiency and profit.

-

Battery packs in electric HGVs can add 2–4 tonnes of extra weight. Without lighter trailers, payloads shrink and operating margins suffer. Berkeley’s composite builds offset that weight, ensuring EV adoption doesn’t come at the expense of range or revenue.

-

Every tonne of weight removed from a trailer reduces CO₂ emissions. A 2-tonne weight saving cuts fuel use — and emissions — by up to 8% per trip. At fleet scale, that’s thousands of tonnes of carbon avoided each year, helping operators meet Net Zero and customer ESG demands.

Who we work with

Logistics and haulage fleets

Reduce fuel costs and increase payload for trunking and long-haul routes.

Grocery and retail distribution

Maximise efficiency on multi-drop and high-frequency deliveries.

Refrigerated fleets

Offset fridge unit weight to keep payload at legal GVW.

Waste and recycling operators

Walking-floor trailers gain payload and efficiency benefits.

Proven results

Fuel savings: 7.4%

(based on 13.6m trailer, Cambridge CSRF data)

Extra payload: 6 roll cages

on a single deck trailer

Our solutions

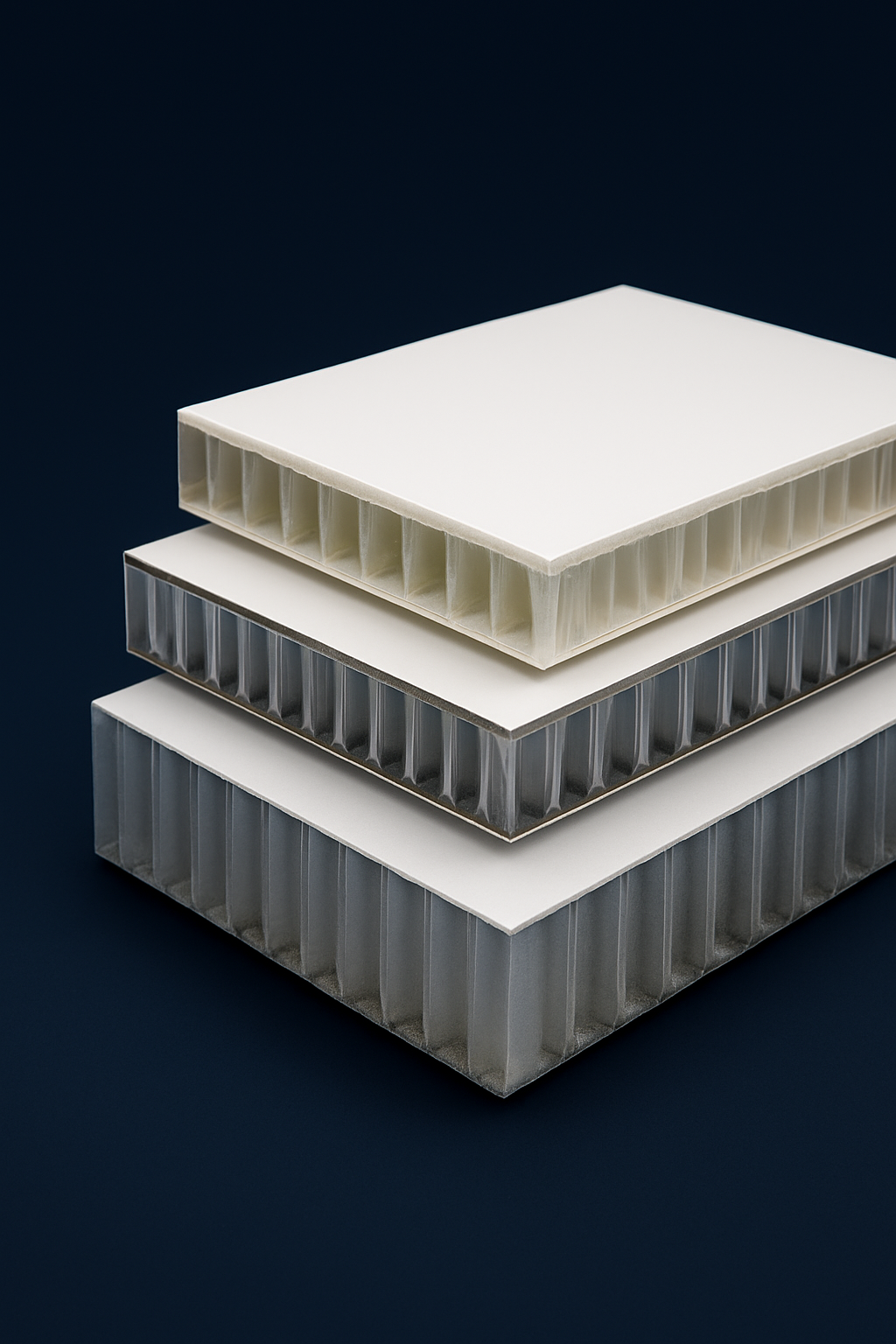

Lightweight Composite Panels

Berkeley manufactures advanced bonded composite panels designed for commercial vehicle trailers. Our panels deliver maximum weight reduction without compromising strength, safety, or durability.

Sidewalls & Flooring

Lightweight yet durable panels engineered to reduce tare weight and improve payload.

Decking Solutions

High-strength sandwich panels with outstanding load resistance for long-lasting performance.

Specialist Builds

Custom-engineered solutions for refrigerated, modular, and specialist transport applications.

Electric Fleet Solutions

Supporting Electrification

The EV Challenge

Electric HGV battery packs can add 2–4 tonnes, cutting payload and limiting operational flexibility. For many fleets, this makes the transition to electric costly and complex.

Our Solution

Berkeley lightweight composite trailers recover lost payload capacity and extend driving range. By offsetting battery weight, they protect efficiency while supporting zero-emission targets.

The Benefit

Fleets achieve compliance without compromise: reduced tare weight, more payload, and financially sustainable electric operations.

Ready to start saving?

Lightweighting Guide

Comprehensive overview of fuel, cost, and payload benefits.

Request a Cost-Saving Calculation

Personalised analysis based on your fleet and mileage.